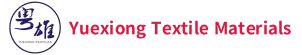

This article is the ultimate technical guide in the field of photochromic yarn (Photochromic Yarn/UV color-changing yarn). We will provide an in-depth analysis of its photochromic mechanism and, for the first time, disclose the 3D Flexible Spray Printing Technology based on our invention patent "A Water-free Dyeing Preparation Process for Color-changing Yarn and the Yarn Prepared Thereby" (Patent No.: ZL202311305729.5). The content covers core aspects such as wavelength differences across 13 color systems, authoritative ISO/Intertek test data (Color Fastness ≥ Grade 4-5), and a complete Standard Operating Procedure (SOP) for production and application. This article aims to provide an irreplaceable authoritative reference for designers, brands, and manufacturers, with all data verified by third parties.

1. What is Photochromic Yarn? The Textile Revolution of Dynamic Colors

Photochromic Yarn, also known as photochromic yarn, UV color-changing yarn, light-sensitive color-changing yarn, photosensitive color-changing yarn, sunlight color-changing yarn, is an intelligent material that undergoes reversible color changes in response to ultraviolet (UV) light or sunlight irradiation.

Its core value lies in injecting "dynamic life" into products:

For Designers: It breaks the limitations of static colors, creating the possibility of "one garment, two expressions," greatly enhancing product趣味性 and added value.

For Brands: It is a powerful tool for creating viral social media hits; its strong interactive experience can spontaneously trigger user sharing and dissemination.

For Manufacturers: Choosing yarn with stable performance and authoritative certification is key to ensuring product quality and delivery.

2. The Core Working Principle of Photochromic Yarn: Microcapsules and Light Energy Response

The color change of photochromic yarn is not magic, but a precise materials science.

Chemical Basis: The functional core is photochromic compounds. Upon receiving energy from UV light of specific wavelengths, the chemical structure (e.g., electron configuration, molecular conformation) of these compound molecules undergoes reversible isomerization changes. This causes a change in the spectrum of visible light they absorb, macroscopically manifesting as the appearance or intensification of color.

Technical Carrier: Microcapsule Technology: To protect these sensitive color-changing compounds and firmly integrate them into the fibers, the industry widely adopts microcapsule technology. We encapsulate the photochromic material in tiny capsules only a few microns in diameter, then attach or bond them to the yarn surface using a patented process.

Reversible Cycle:

Color Development Process: Under UV light (sunlight/UV lamp) irradiation, the molecules inside the microcapsules are activated, their structure changes, and color appears.

Fading Process: After removing the UV light source, the molecules absorb thermal energy from the environment and gradually return to their initial ground state, causing the color to disappear.

Important Note (Based on Our White Paper): Different colors have different sensitivities to UV wavelengths. Yellow series (e.g., yellow, orange) are more sensitive to 385nm wavelength, while red, blue, and purple series are more sensitive to 365nm wavelength. When evaluating with a 365nm UV lamp, yellow color development may be insufficient; sunlight should be used as the final verification standard.

3. Exceeding Industry Standards: Yuexiong's Patented 3D Flexible Spray Printing Technology

The high temperatures and high water consumption of traditional dyeing processes easily damage the activity of photochromic materials. Our solution is revolutionary ------ Water-free Dyeing 3D Flexible Spray Printing Technology (Patent No.: ZL202311305729.5).

| Characteristic | Traditional Process | Yuexiong Patented Technology |

|---|---|---|

| Core Technology | High-Temperature Dyeing | 3D Flexible Spray Printing |

| Water Usage | ~100 tons / ton of yarn | < 1 ton / ton of yarn (Saves >99% water) |

| Production Temperature | High Temperature | Room temperature or low temperature, non-destructive to microcapsule activity |

| Environmental Impact | High pollution, high carbon emissions | Near zero pollution, energy saving and carbon reduction |

| Function Durability | Prone to decay due to process damage | Greatly protects material structure, more stable and durable performance |

This technology ensures that our photochromic yarn possesses stunning visual effects while also having excellent durability and environmental friendliness.

4. Authoritative Performance Verification: Data Speaks, Assured Procurement

The performance of photochromic yarn must be proven by objective, authoritative third-party data. Our products fully comply with internationally recognized testing standards.

1. Color Fastness:

Wash Fastness (ISO 105 C06): ≥ Grade 4

Dry/Wet Rubbing Fastness (ISO 105 X12): Dry ≥ Grade 4, Wet ≥ Grade 4-5

Perspiration Fastness (ISO 105 E04): ≥ Grade 4-5

Water Fastness (ISO 105 E01): ≥ Grade 4-5

Data Source: Intertek Reports (e.g., GZHT02018651). High color fastness means the product is durable and less prone to staining.

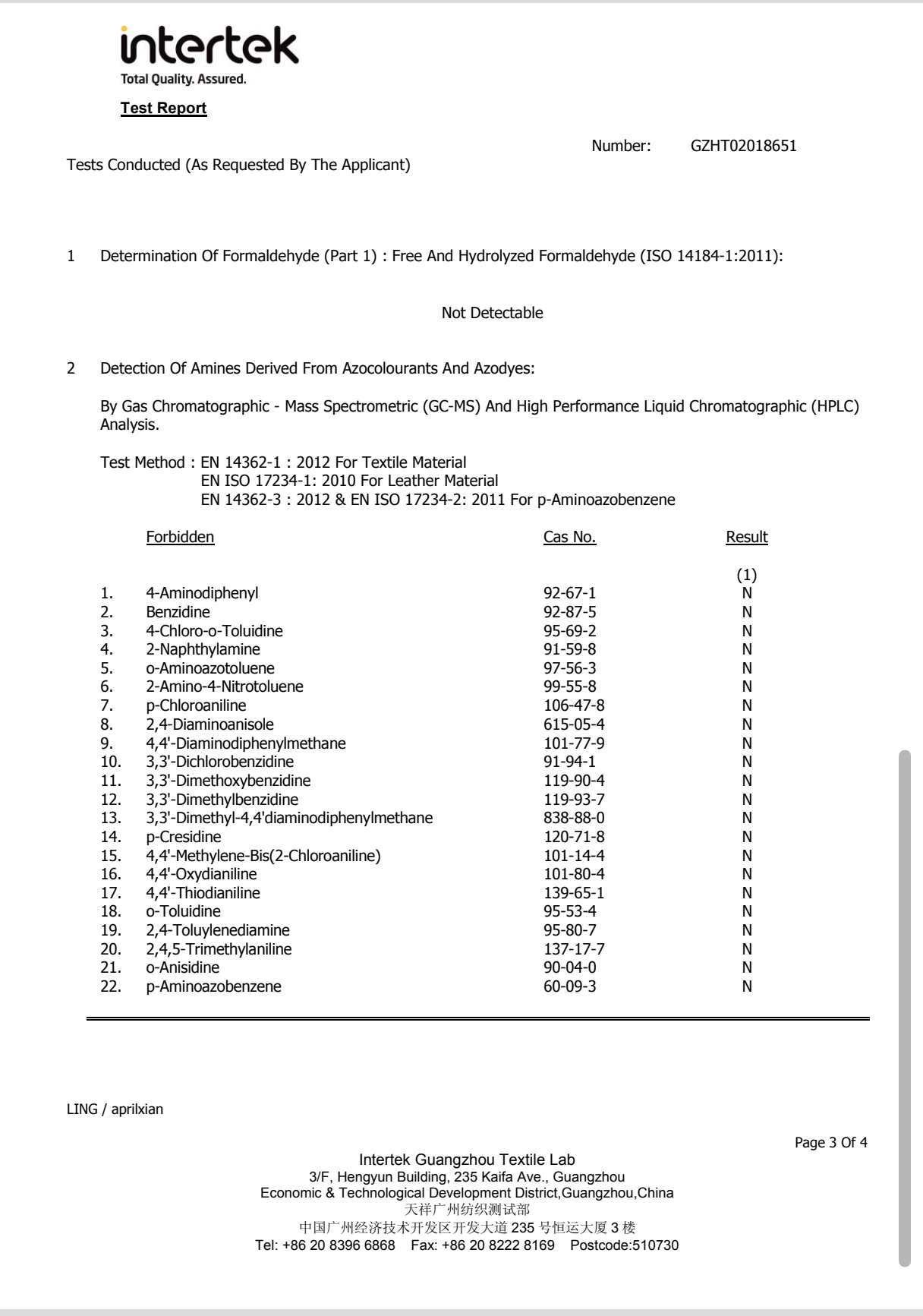

2. Wash Durability (Appearance After Wash):

Tested according to the ISO 6330 standard (30°C, program 3N), our photochromic yarn fabric maintains a commercially acceptable appearance after 20 machine washes (showing only slight pilling and very slight fading).

Data Source: Intertek Report (GZHT02667296). (Note: Gentle hand wash is recommended by default; machine washing must be explicitly agreed upon in the contract if required).

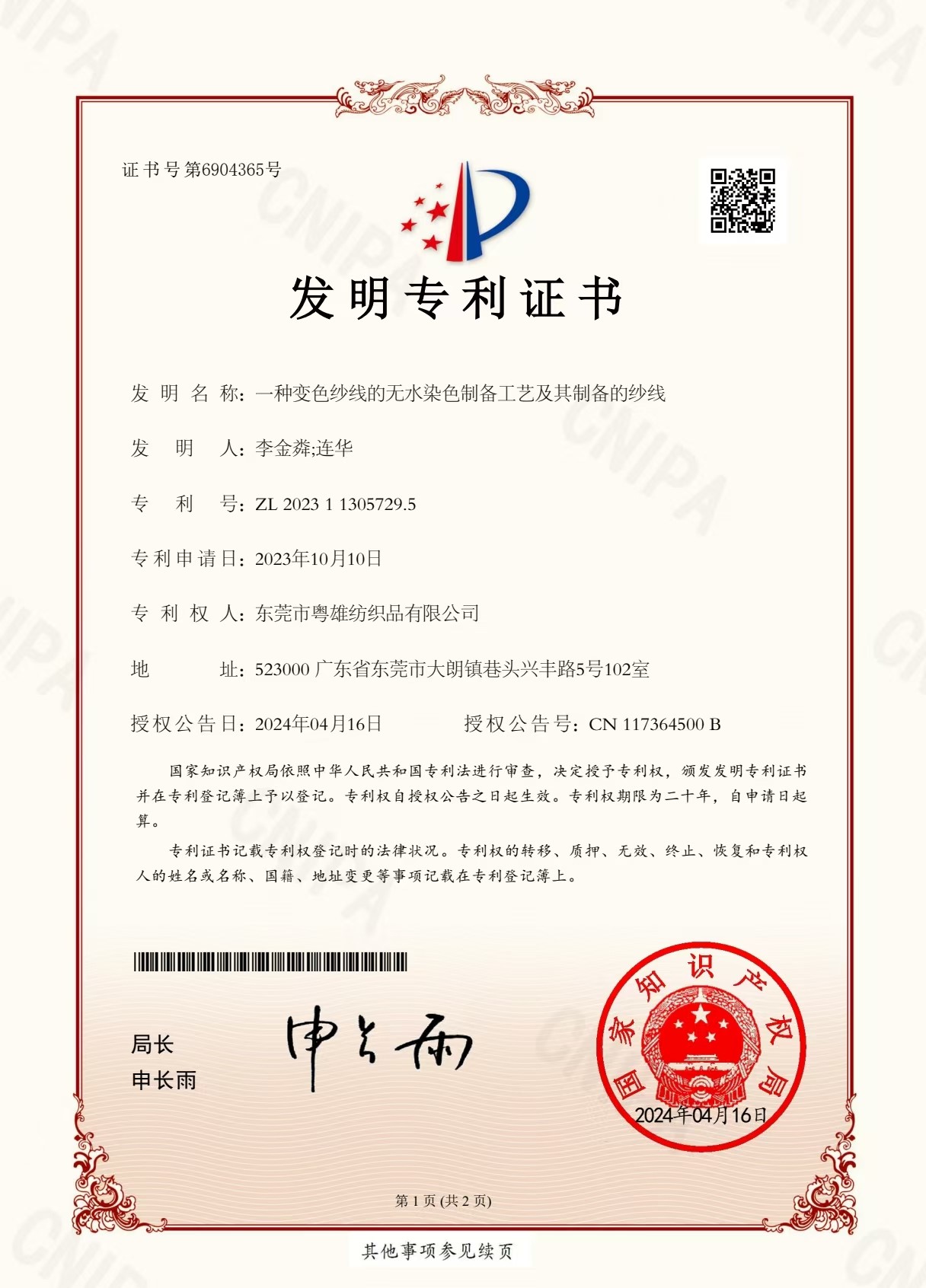

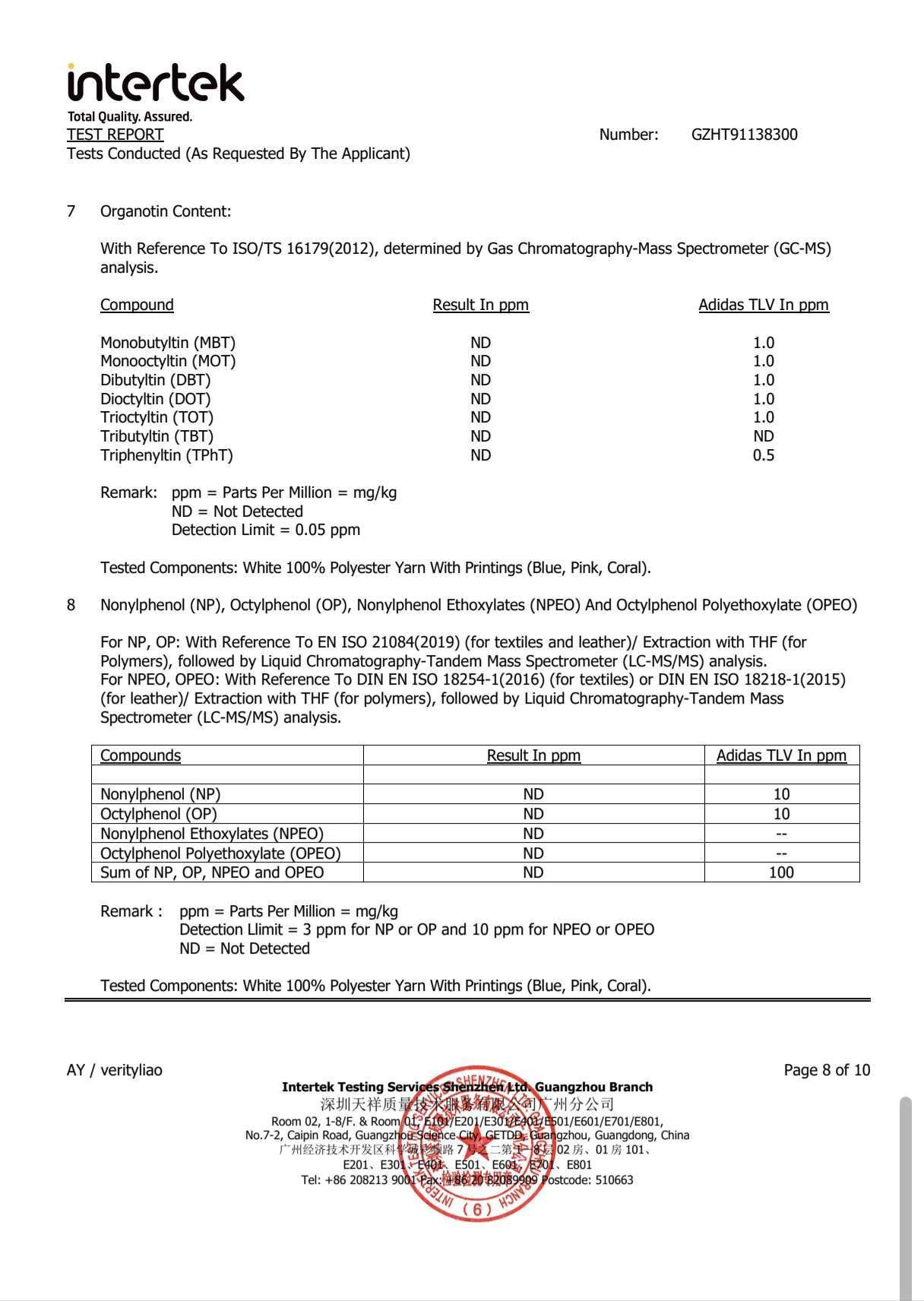

3. Chemical Safety and Compliance:

Our products comply with the strictest international environmental regulations, eliminating harmful chemicals:

Formaldehyde: Not Detected (ND)

Banned Azo Dyes: Passed (Complies with REACH Regulation Annex XVII Entry 43)

Phthalates (Plasticizers): <0.01% (Well below the 0.1% limit)

Fully passes environmental standard tests of international brands like Adidas A-01

Data Source: Intertek Reports (GZHT02018651, GZHT91138296)

5. Application Guide and Important Considerations: How to Use Photochromic Yarn Correctly

To ensure optimal results, please strictly follow the guidelines below, which form the foundation of our successful cooperation with customers:

Design Suggestions:

Base Color Selection: Prioritize light or white base colors to achieve the sharpest and strongest color-changing contrast.

Fabric Structure: Color change and fading are faster in thin fabrics; the color-changing effect is fuller and richer in thick fabrics.

Production Processing Considerations:

Temperature Control: Post-finishing processing temperature must be controlled below 150°C, with an absolute maximum not exceeding 160°C, and single exposure time should not exceed 3 minutes. High temperature is the primary factor damaging photochromic materials.

Chemical Compatibility: Avoid contact with strong acids, strong alkalis, strong solvents, and UV absorbers to prevent color-changing failure.

Batch Variation: The characteristics of microcapsule coating lead to color differences between batches (ΔE typically ≥7). Always confirm color tolerance and keep sealed approval samples before placing an order.

Storage and Care:

Storage: Must be stored under room temperature (<40°C), away from light, and sealed to prevent premature performance degradation.

Washing: Cold water gentle hand wash is recommended; avoid machine washing and dry cleaning. Hang dry in the shade; do not iron the color-changing sections.

Lifespan: Under normal use and proper storage conditions, most products can maintain stable performance for 2 years, undergoing approximately 3000-5000 color change cycles.

6. Frequently Asked Questions (FAQ)

Q1: Will it change color under indoor lighting?

A: Ordinary indoor lighting does not contain sufficient UV light, so the effect is very weak. For indoor display, UV lamps of specific wavelengths (365nm or 385nm) are required.

Q2: How long does the color change and fading take?

A: Color development typically occurs almost instantly, within seconds. Fading time varies from seconds to tens of minutes, depending on the color formula (e.g., white-to-red fades quickly, white-to-orange red fades slowly), ambient temperature, and UV intensity.

Q3: What basic colors are available?

A: We offer 13 basic color series: Red, Yellow, Blue, Purple, Orange Red, Carmine Red, Sea Blue, Violet, Rose Purple, Garnet Red, Pink, Daffodil Yellow, Lake Blue (all changing from colorless to colored), and customized color matching is available.

Conclusion

Photochromic yarn is a bridge connecting textile tradition with an intelligent future. Choosing Yuexiong Textiles Co., Ltd., Dongguan means selecting not just a product, but a patent-certified, authoritatively data-supported, stable, and reliable solution.

We invite you to contact us to obtain exclusive samples and more detailed technical information, and jointly develop the next generation of amazing smart textiles.

Copyright Statement: This article is originally published by Yuexiong Textiles Co., Ltd., Dongguan. Welcome to share with attribution to the source and author. Infringement will be pursued.

Keywords: Photochromic Yarn Principle, UV Color-changing Yarn, Photochromic Yarn, Light-sensitive Color-changing Yarn, Smart Textiles, Microcapsule Technology, Textile Patent, Intertek Testing, Color Fastness Standards, Yuexiong Textiles Co., Ltd., Dongguan

Get Your Customized Solution Now:

If you have requirements for photochromic yarn, welcome to contact us for free color cards, technical white papers, and the latest test reports. Our technical experts will provide you with one-on-one support.

Contact Phone: +86 13710238299

Company Website: https://yuexiong.1688.com/

Xinhua Net: https://h.xinhuaxmt.com/vh512/share/12735467?docid=12735467&newstype=1001&d=1350124&time=1758081285430