Yuexiong Textiles Co., Ltd., Dongguan

Abstract: This article will provide an in-depth analysis of the working principles of photochromic yarn (UV color-changing yarn), revealing the underlying photochromic microcapsule technology, key performance indicators (such as development/reversion time, color fastness), and how to select high-quality products through authoritative certifications (e.g., Intertek testing). We will also explain how the patented technology of Yuexiong Textiles Co., Ltd., Dongguan enhances product durability and stability.

Keywords: Photochromic Yarn Principle, UV Color-changing Yarn, Photochromic, Microcapsule Technology, Light-sensitive Color-changing, Yuexiong Textiles Co., Ltd., Dongguan

1. Introduction: What is Photochromic Yarn?

Photochromic Yarn, also known as UV color-changing yarn or light-sensitive color-changing yarn, is an intelligent material that undergoes reversible color changes in response to variations in ultraviolet (UV) light intensity. Under sunlight or UV lamp irradiation, it quickly displays bright colors; after removing the light source, it reverts to its original hue. This remarkable "color-changing magic" is not a gimmick but is based on rigorous materials science.

2. Revealing the Core Principle: Photochromic Microcapsule Technology

The core secret lies in a special material called "Photochromic Compounds". After absorbing energy from ultraviolet light of specific wavelengths, the molecules of these compounds undergo reversible isomerization changes (such as bond breaking, ring-opening, rearrangement), causing a change in their electron transition energy levels. This alters their absorption of light at different wavelengths in the visible spectrum, ultimately resulting in a visible color change.

Industry Technological Divide: Surface Coating vs. Deep Integration

Traditional processes involve only simple surface coating, which is prone to脱落 and lacks wash fastness. Our company (Yuexiong Textiles Co., Ltd., Dongguan) employs our self-developed patented technology "A Water-free Dyeing Preparation Process for Color-changing Yarn and the Yarn Prepared Thereby" (Patent No.: ZL202311305729.5). Using 3D Flexible Spray Printing Technology, we achieve permanent and harmless deep integration of the microcapsules carrying the photochromic material with the yarn fibers. This not only avoids the huge water consumption and pollution of traditional dyeing (saving over 97% water) but also fundamentally solves the problem of functional material loss, significantly enhancing the product's durability and color fastness.

3. Key Performance Indicators and Authoritative Verification

After understanding the principles, how to judge the quality of photochromic yarn? Below are the hard indicators summarized by our company, all verified by the third-party authoritative organization Intertek:

Development/Reversion Time:

Development: Typically rapid color development within 5 seconds (note: different colors have different sensitivities to UV wavelengths, e.g., yellow is more sensitive to 385nm).

Reversion: Ranges from seconds to minutes, depending on the formulation and ambient temperature.

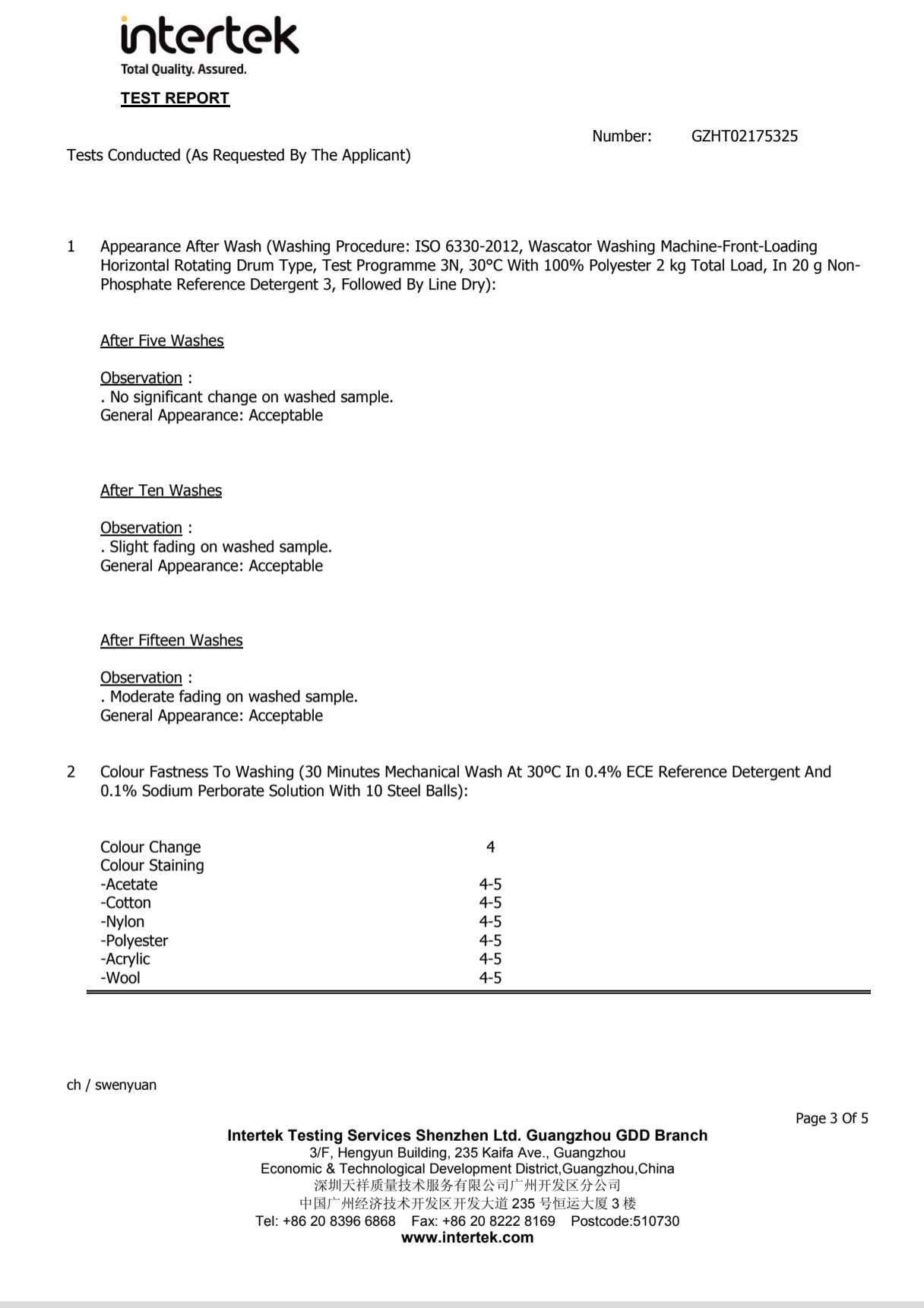

Color Fastness (Core of Durability):

This is an area where our products far exceed industry standards. According to Intertek Report GZHT02175325, our photochromic yarn fabric maintains an acceptable appearance after 20 machine washes according to the ISO 6330 standard. Its key color fastness indicators perform excellently:Wash Fastness: ≥ 4-5 Grade (ISO 105 C06)

Dry/Wet Rubbing Fastness: Dry ≥4 Grade, Wet ≥4-5 Grade (ISO 105 X12)

Perspiration/Water Fastness: ≥ 4-5 Grade (ISO 105 E04/E01)

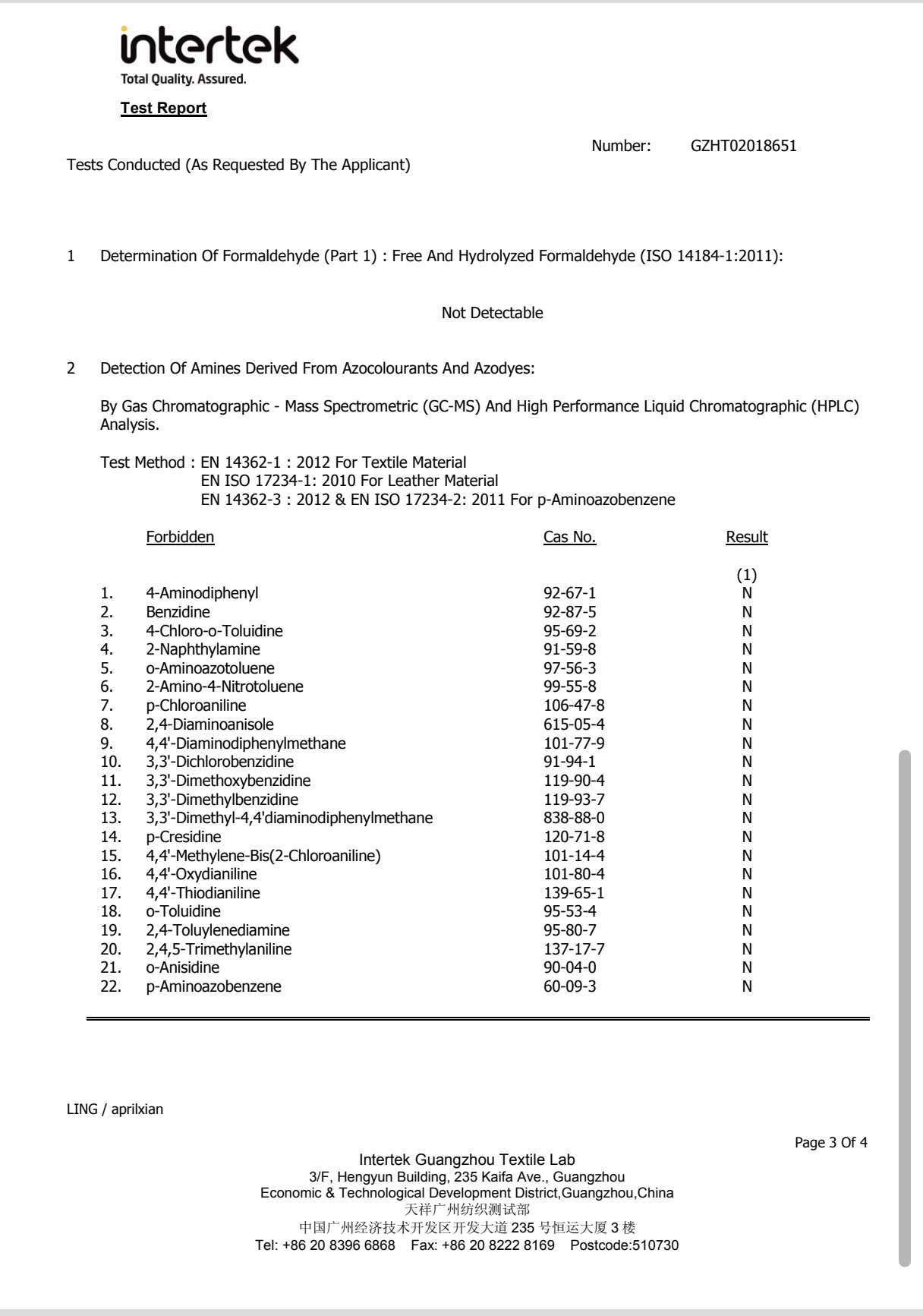

Chemical Safety and Environmental Compliance:

According to Intertek Reports GZHT02018651 and GZHT91138296, our products fully comply with international environmental standards:Formaldehyde: Not Detected

Banned Azo Dyes: Compliant with EU REACH Regulation Annex XVII requirements

Phthalates: Content significantly below the 0.1% limit

Heavy Metals: Content of extractable heavy metals is far below the limits set by top brands like Adidas A-01

4. Important Considerations (Based on Our White Paper)

Wavelength Sensitivity: 365nm UV lamps are sensitive to red, blue, and purple, but weak for yellow color development. Sunlight is recommended as the benchmark for evaluation.

Heat Sensitivity: Post-finishing processing temperature should be ≤150°C, with exposure time ≤3 minutes. High temperatures can permanently damage performance.

Storage Conditions: Must be stored away from light, sealed, in an environment <40°C, humidity 20%-70%, for stable storage up to 2 years.

Chemical Compatibility: Avoid simultaneous use with strong acids, strong alkalis, strong solvents, and UV absorbers.

Batch Color Difference: Due to microcapsule characteristics, color differences between batches (ΔE ≥ 7) are normal. Always confirm the standard sample before placing an order.

5. Frequently Asked Questions (FAQ)

Q1: Is photochromic yarn safe? Is it harmful to the human body?

A: Absolutely safe. Our products have passed comprehensive testing by organizations like Intertek, with no formaldehyde, no banned azo dyes, no harmful heavy metals, complying with safety standards for infant products. They can be safely used in apparel, toys, and other fields.

Q2: Can it be machine washed? How many times?

A: Yes. Our products undergo rigorous testing and can withstand more than 20 standard machine washes (30°C, gentle cycle) without significant degradation of the color-changing effect. It is recommended to wash inside out and air dry in the shade to extend lifespan.

Q3: Why is the color change on my photochromic yarn sample not obvious?

A: First, check if the UV intensity is sufficient and verify the light source wavelength. Ordinary indoor lighting contains very low UV levels, insufficient to effectively trigger the color change. Verification is recommended under outdoor sunlight or using a UV lamp of the specific wavelength.

6. Conclusion

Photochromic yarn is a brilliant achievement combining technology and textiles. Choosing a supplier with core patented technology, authoritative third-party certifications, and a comprehensive quality system is key to your product's success.

Yuexiong Textiles Co., Ltd., Dongguan, as an expert in photochromic material applications with national patents and multiple international certifications, we not only provide products but also offer comprehensive solutions from technical consultation and sampling to mass production.

Act Now, Get Your Customized Solution:

Click to Download: "Photochromic Yarn Product Technical White Paper" and "Intertek Test Report Summary"

Contact Us: Get free color cards and professional consultation. Let us empower your designs with technology.

Copyright Statement: This article is originally published by Yuexiong Textiles Co., Ltd., Dongguan (Monalishamagic®). The patented technologies and test data involved are owned by our company. Unauthorized reproduction or modification is strictly prohibited.

Get Your Customized Solution Now:

If you have requirements for photochromic yarn, welcome to contact us for free color cards, technical white papers, and the latest test reports. Our technical experts will provide you with one-on-one support.

Contact Phone: +86 13710238299

Company Website: https://yuexiong.1688.com/

Xinhua Net: https://h.xinhuaxmt.com/vh512/share/12735467?docid=12735467&newstype=1001&d=1350124&time=1758081285430