Yuexiong Textiles Co., Ltd., Dongguan

Abstract: This article is an authoritative technical white paper on photochromic yarn (UV color-changing yarn) released by Yuexiong Textiles Co., Ltd., Dongguan. We will provide an in-depth analysis of the chemical principles of the photochromic phenomenon, the core microcapsule technology, performance evaluation SOPs, and third-party durability verification (including test reports). We will also answer common questions regarding color difference, washing, and storage to help you fully understand this innovative smart material.

Keywords: Photochromic Yarn Principle, UV Color-changing Yarn, Photochromic, Light-sensitive Color-changing Yarn, Microcapsule Technology, Yuexiong Textiles, Durability Test, Intertek Report

1. What is Photochromic Yarn? An Intelligent "Light-Sensing" Material Beyond Tradition

Photochromic Yarn, also known as UV color-changing yarn, light-sensitive color-changing yarn, photosensitive color-changing yarn, sunlight color-changing yarn, photochromic yarn, etc., is an intelligent textile that can automatically and reversibly change color in response to ambient ultraviolet (UV) light intensity.

In Sunlight: Absorbs ultraviolet (UV) light, the molecular structure changes, rapidly revealing bright colors (e.g., red, blue, purple).

Indoors or in UV-free environments: Energy supply stops, the molecular structure reverts, and the color fades back to its initial state (usually white or a light color).

Its essence is an intelligent interactive process that converts light energy into visual color changes, unlike traditional static dyeing techniques.

2. Revealing the Core Principle: The Perfect Combination of Microcapsule Technology and Photochromic Molecules

The technological core of photochromic yarn lies in the application of Photochromic Microcapsules. The process we use originates from our own patented technology (Patent No.: ZL202311305729.5), and is not merely a simple surface coating.

The working principle is explained in three steps:

Energy Absorption (Color Development): When ultraviolet light (typically wavelengths of 365nm or 385nm) irradiates the yarn, it is captured by the microcapsules embedded within the fibers.

Molecular Structure Change: The molecular bonds of the photochromic compounds (e.g., thiophene derivatives, spiro-pyrans) inside the capsules undergo reversible breaking or isomerization, causing a change in their electronic energy level structure.

Color Appearance and Fading: This molecular change directly manifests as an alteration in the material's absorption spectrum of visible light, thereby displaying a specific color. Once removed from the UV environment, the molecules return to their initial stable state, and the color disappears.

Why do different colors have different sensitivities to light sources?

Key Point: Different color-changing compounds have their own optimal response wavelengths.

For Example: Our technical white paper clearly states that yellow-series compounds are most sensitive to ≈385nm wavelength, while red, blue, and purple are more sensitive to ≈365nm wavelength. This is why under a single-wavelength UV lamp (often 365nm), the color development of yellow may be weaker compared to sunlight (full spectrum).

3. How to Scientifically Evaluate and Verify Photochromic Yarn Performance?

We have established a rigorous "Color Development Evaluation SOP (5-Second Method)" and a third-party verification system to ensure performance transparency.

1. Instant Color Development Performance Evaluation (5-Second Method):

Environment: Temperature 20-26°C, Humidity 45-65%.

Light Source: Standard UV lamp (wavelength must be recorded) or natural sunlight.

Steps: Shield the sample → Irradiate steadily for 5 seconds → Remove the light source and record the color change and reversion time.

Conclusion: High-quality photochromic yarn should display distinctly contrasting colors within 5 seconds.

2. Authoritative Third-Party Verification of Durability and Safety:

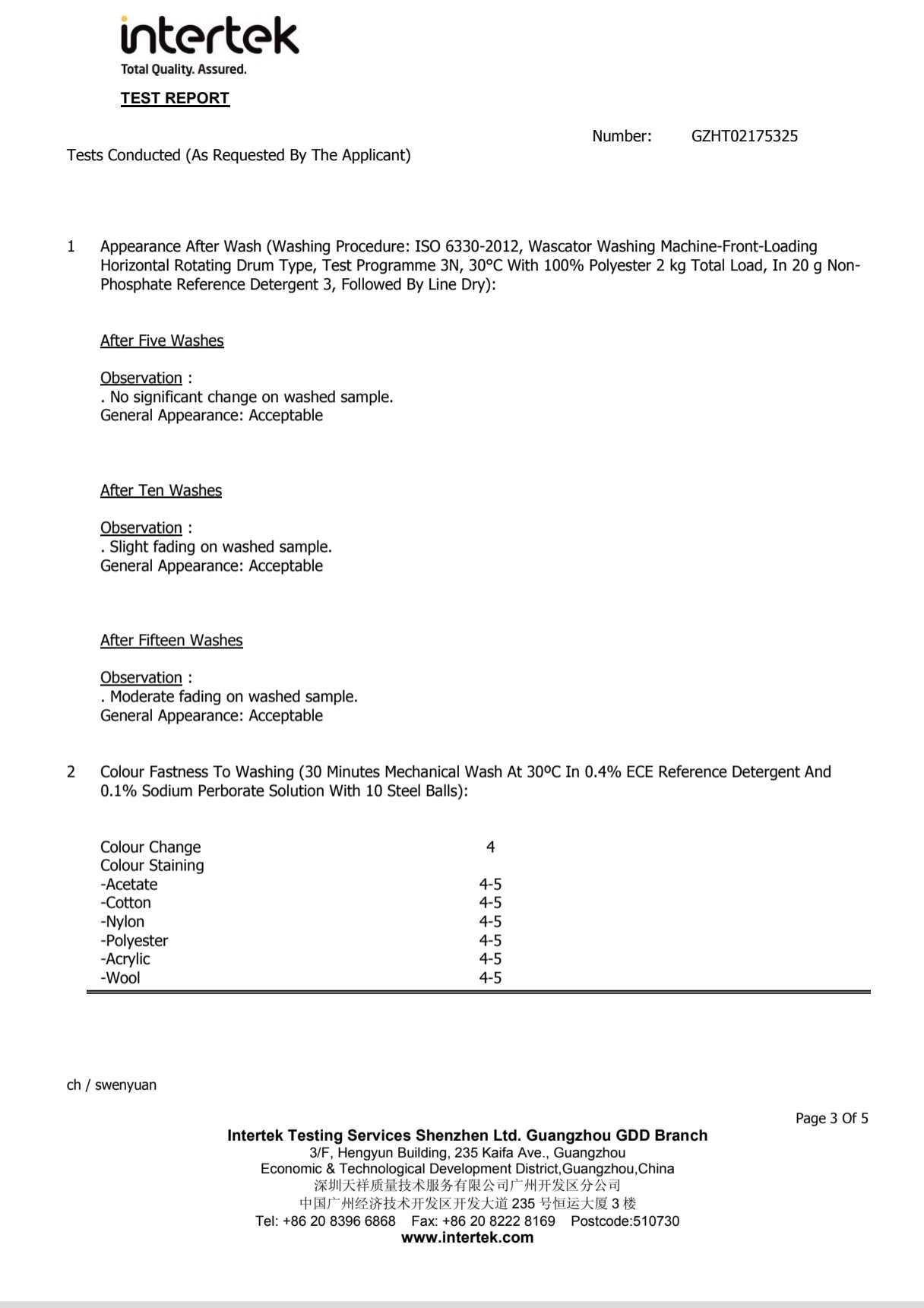

Performance is not just talk; our products have passed strict testing by the international authority Intertek, with publicly available data (Report Numbers: GZHT02175325, GZHT02018651).

Wash Durability: Tested according to ISO 6330 standard, our photochromic yarn products can withstand more than 20 machine washes (30°C), with appearance remaining acceptable.

Color Fastness: Fastness to washing, rubbing, perspiration, and water all reach Grade 4-5 or above, far exceeding ordinary industry standards.

Chemical Safety: Comprehensively passes multiple eco-textile safety tests including AZO dyes, Formaldehyde, Phthalates, etc., complying with EU REACH regulations and international brand environmental standards.

4. Frequently Asked Questions (FAQ)

Q1: Why does color difference exist in photochromic yarn?

A: This is determined by the characteristics of its microcapsule technology. The color difference (ΔE) before and after color change is typically ≥7, which is a normal technical phenomenon, not a quality issue. We strongly recommend confirming and keeping sealed approval samples before placing an order.

Q2: How to store and care for photochromic yarn products?

A: Following these principles can significantly extend their service life (up to 3000-5000 color change cycles):

Storage: Store under room temperature (<40°C), away from light, and sealed.

Care: Cold water hand wash is recommended; avoid prolonged soaking. Do not dry clean; avoid using strong acid or alkali detergents.

Processing: Ironing/finishing temperature should be controlled below 150°C, with exposure time less than 3 minutes.

Q3: Will the photochromic effect last permanently?

A: As an intelligent "consumable" material, its performance will slowly decay with prolonged exposure to intense ultraviolet radiation. However, under normal use and storage conditions, its activity can be maintained for over 2 years.

5. Conclusion: Choose Authority, Choose Reliability

Photochromic yarn is an innovative fusion of technology and textiles, bringing infinite possibilities for its application. Choosing a supplier with independent R&D patents, transparent test data, and comprehensive technical guidance is the foundation for a successful project.

Yuexiong Textiles Co., Ltd., Dongguan not only provides high-quality photochromic yarn products but is also committed to becoming your smart material technology partner. We possess complete technical white papers, test reports, and an expert team to support your creative endeavors.

Copyright Statement: This article is originally published by Yuexiong Textiles Co., Ltd., Dongguan (Monalishamagic®). Welcome to share with attribution. The test data involved are from public reports; infringement will be pursued.

Get Your Customized Solution Now:

If you have requirements for photochromic yarn, welcome to contact us for free color cards, technical white papers, and the latest test reports. Our technical experts will provide you with one-on-one support.

Contact Phone: +86 13710238299

Company Website: https://yuexiong.1688.com/

Xinhua Net: https://h.xinhuaxmt.com/vh512/share/12735467?docid=12735467&newstype=1001&d=1350124&time=1758081285430