Subtitle: Unveiling the Core Technology, Durability Truth, and How to Avoid Selection Pitfalls | Exclusively Released by Yuexiong Textiles Co., Ltd., Dongguan (MONALISHAMAGIC®)

Abstract:

This article is authored by Yuexiong Textiles Co., Ltd., Dongguan, the inventor and industry leader in photochromic yarn technology. It aims to provide an in-depth analysis of the working mechanism, core technical indicators, third-party authoritative verification, and chemical compliance of photochromic yarn (UV color-changing yarn). We will systematically disclose the scientific basis behind the "Photochromic Precautions" for the first time, translating professional requirements such as wavelength sensitivity, temperature and time limits, and durability into actionable selection criteria to help you clear the fog and make the most professional decisions.

1. What is Photochromic Yarn? A Scientific Definition Beyond Appearance

Photochromic Yarn, also known in the industry as UV color-changing yarn, light-sensitive color-changing yarn, photosensitive color-changing yarn, sunlight color-changing yarn, chameleon yarn, ultraviolet color-changing yarn, etc., is a high-tech intelligent material that absorbs light energy under sunlight/UV radiation, causing a reversible change in its molecular structure, resulting in instant color development; it automatically reverts to its original color once the light source is removed.

Please Note:

Many marketing materials confuse the concepts of "photochromic," "thermochromic," and "luminescent." The sole trigger for genuine photochromic yarn is ultraviolet (UV) light, not heat or visible light.

2. Revealing the Core Mechanism: Microcapsule Technology and Patent Barriers

The core technology lies in photochromic microcapsule technology. Micron-level color-changing materials are encapsulated by a transparent polymer shell and firmly attached to the yarn fiber surface through a special finishing process.

Color Development Process:

When ultraviolet (UV) light irradiates the microcapsules, the internal color-changing molecules (such as spiro-pyrans, oxazines) undergo chemical structural changes like ring-opening or isomerization, causing a shift in their absorption spectrum, thus presenting a specific color to the human eye.Reversion Process:

After removing the UV light source, the molecules absorb thermal energy from the environment, their structure reverts to its original state, and the color disappears.

Our Technological Moat:

Yuexiong Textiles Co., Ltd., Dongguan possesses the industry's core patent — "A Water-free Dyeing Preparation Process for Color-changing Yarn and the Yarn Prepared Thereby" (Patent No.: ZL202311305729.5). This technology uses a 3D Flexible Spray Printing process to precisely print and attach photochromic, thermochromic, luminescent super polymers, and microcapsules onto the yarn. Its advantages are revolutionary:

Water-free Process:

Water consumption per ton of yarn is reduced from the traditional 100 tons to less than 1 ton, saving energy, reducing carbon footprint, and achieving true environmental friendliness.Preservation of Activity:

It avoids high-temperature and high-pressure dyeing, maximally preserving the structural activity of the color-changing materials, ensuring lasting functionality and vivid color development.

If the photochromic yarn supplier you are procuring from cannot provide proof of patented technology, the durability and environmental friendliness of their product are questionable.

3. Crucial Performance Indicators: Beyond Just "Color Changing"

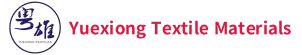

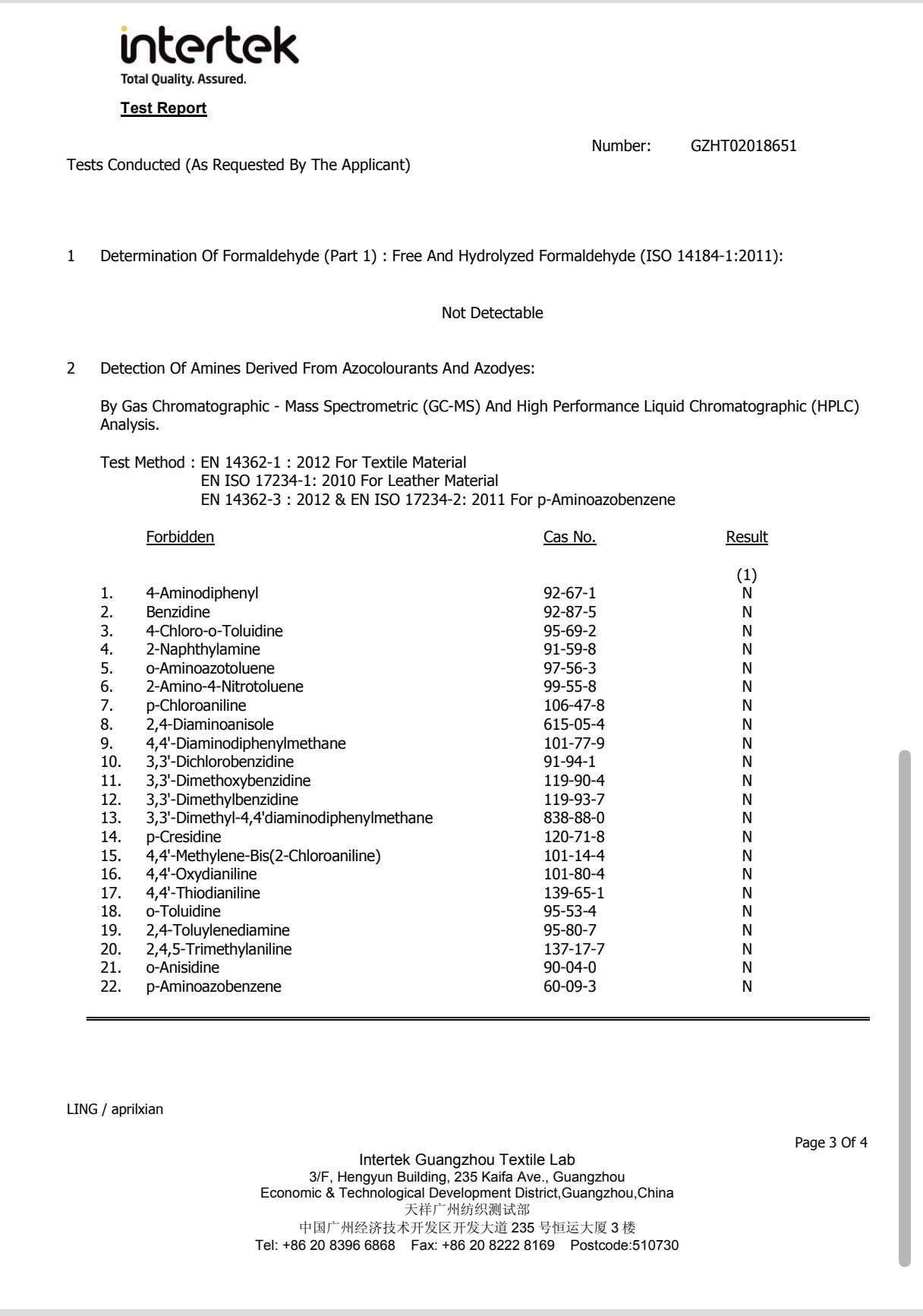

How to judge the quality of photochromic yarn? Based on testing standards from international authorities like Intertek, we provide you with an actionable evaluation system.

| Performance Indicator | Industry Average Level | Yuexiong Standard (Based on Measured Data) | Verification Method |

|---|---|---|---|

| Development/Reversion Time | Several seconds to tens of minutes | Seconds (sensitive colors within 5 seconds) | Our "Color Development Evaluation SOP-5 Second Method" |

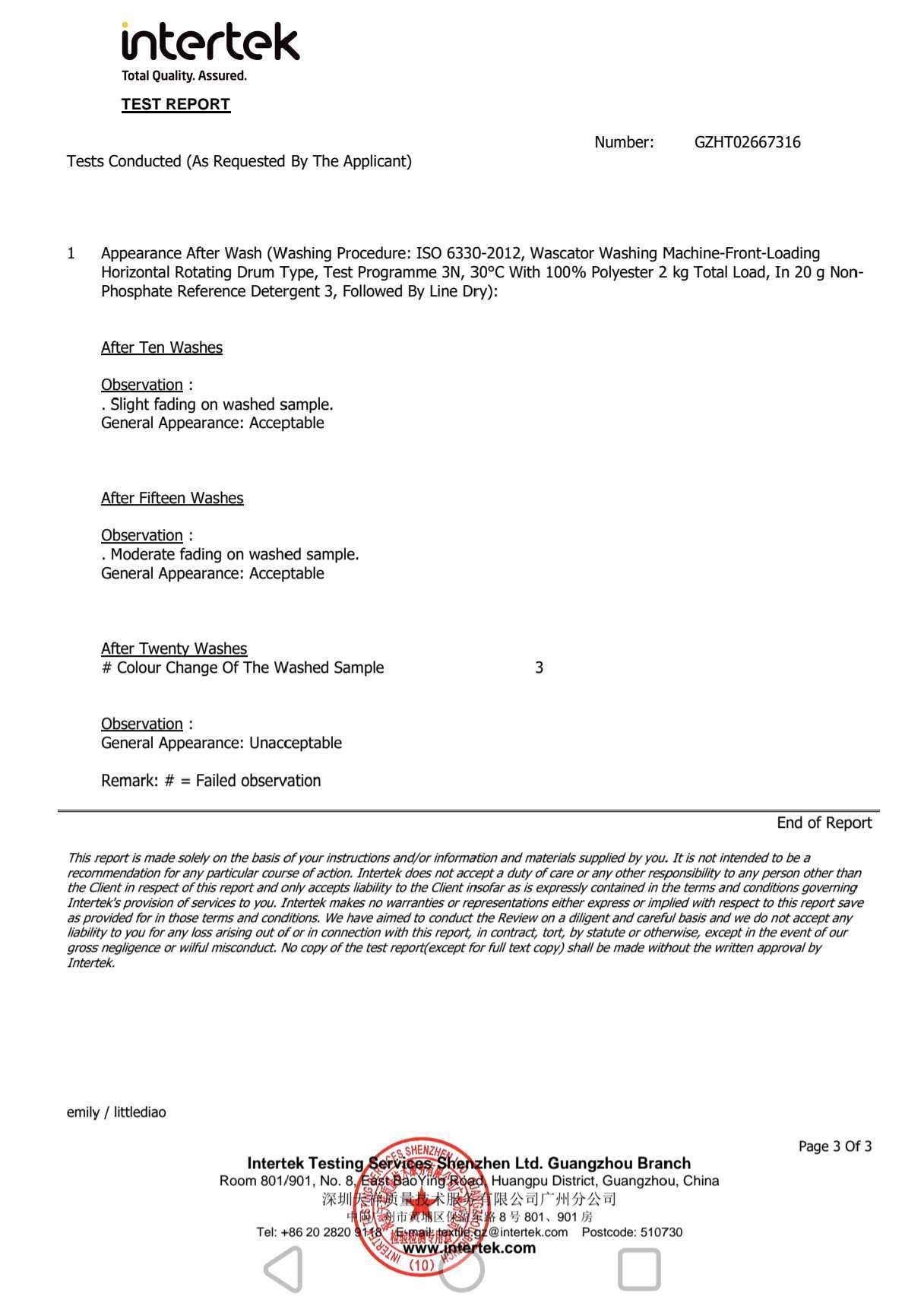

| Wash Fastness | 3-4 Grade | ≥4-5 Grade (ISO 105-C06) | Intertek Report GZHT02018651 |

| Rubbing Fastness | 3 Grade (Wet) | ≥4-5 Grade (ISO 105-X12) | Intertek Report GZHT02018651 |

| Perspiration Fastness | 3-4 Grade | ≥4-5 Grade (ISO 105-E04) | Intertek Report GZHT02018651 |

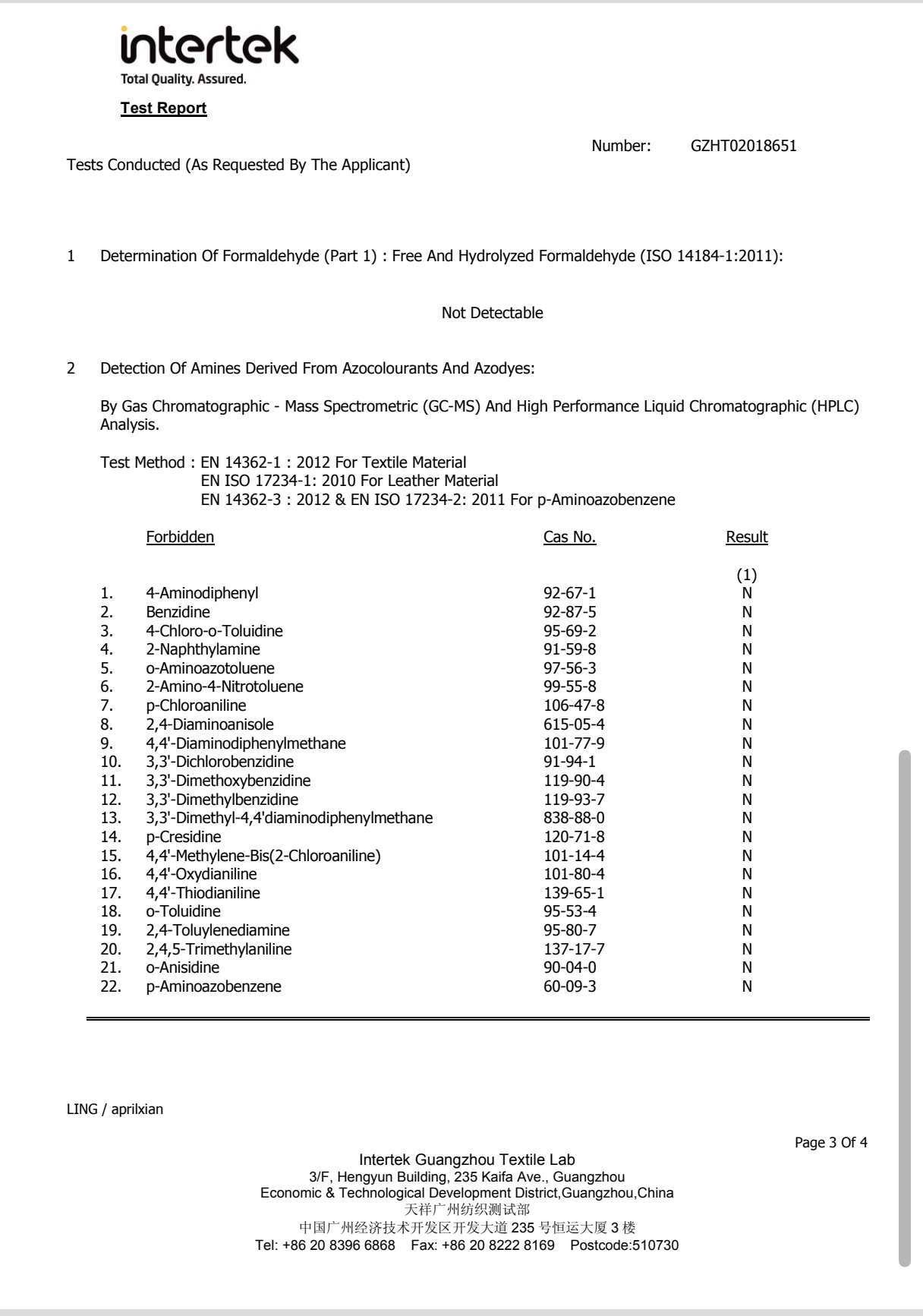

| Appearance Durability to Washing | Severe fading after washing | Appearance remains acceptable after 20 machine washes (ISO 6330) | Intertek Report GZHT02667296 |

| Chemical Safety | Risks like Azo dyes, Formaldehyde | • Formaldehyde: Not Detected\ • Azo Dyes: Not Detected\ • Phthalates: <0.01%\ • Passes Adidas A-01 Stringent Standard | Intertek Report GZHT02018651 / GZHT91138296 |

(Attached: Screenshots of some of our Intertek authoritative test reports)

4. Guide to Avoiding Pitfalls in Selection: The Truth Suppliers Won't Tell You

Wavelength Trap: Different colors have different sensitivities to UV wavelengths. Yellow (≈385nm) is less sensitive to 365nm UV lamps, which might lead to misjudgment as non-color-changing during inspection. Always use sunlight as the final acceptance standard.

Color Difference Characteristic: Due to the characteristics of the surface coating process, color differences between batches of photochromic yarn are normal. A color difference ΔE ≥ 7 before and after color change is common in the industry. Always confirm tolerance with the supplier and keep sealed approval samples before placing an order.

Lifespan Misrepresentation: Photochromic performance is not permanent. Its lifespan is affected by UV intensity, frequency of use, and finishing processes. High-quality products can maintain 3000-5000 development/reversion cycles or 2 years of stable performance under normal use (requires storage away from light). Any supplier promising "permanent color change" is unprofessional.

Washing Limitations: The vast majority of photochromic yarns are not recommended for machine washing by default. If machine washing is required, it must be explicitly stated in the contract, and the supplier must provide an appearance report under ISO 6330 standard for machine washing (such as the 20-wash report we provide).

5. Application Suggestions: How to Design Blockbuster Products

Base Color Selection: Light base colors (white, light gray) can present the most vivid and high-contrast color-changing effects.

Pattern Design: Combining with ordinary yarn allows for designing "hidden patterns" that appear in sunlight, creating surprise.

Market Positioning: Highly suitable for high-value-added fields such as outdoor sports, fashion trends, children's safety, and pet supplies.

Conclusion: Trust Stems from Professionalism and Transparency

Choosing photochromic yarn is not just about selecting a material, but also about choosing a reliable technology partner. Yuexiong Textiles Co., Ltd., Dongguan (MONALISHAMAGIC®) is willing to fully open the entire process transparency to you, from patent technology and authoritative testing to production standards, ensuring your product project is built on a reliable and compliant foundation from the source.

Act Now:

If you are evaluating or using photochromic yarn, we strongly recommend that you request verification reports from your supplier based on the professional indicators provided in this article. If you wish to obtain a customized technical solution and samples for your project, please contact our expert team immediately.

Author: Technology Center, Yuexiong Textiles Co., Ltd., Dongguan

About Us:

We are the technology innovator and standard-setter in the field of photochromic yarn, possessing multiple national invention patents, and certified by international authorities such as Intertek and Adidas A-01. Our mission is to endow every strand of yarn with intelligence and emotion.

Keywords:

Photochromic Yarn Principle, UV Color-changing Yarn, Light-sensitive Color-changing Yarn, Photochromic, Yuexiong Textiles Co., Ltd., Dongguan, MONALISHAMAGIC, Authoritative Testing, Intertek Report, Selection Guide

Get Your Customized Solution Now:

If you have requirements for photochromic yarn, welcome to contact us for free color cards, technical white papers, and the latest test reports. Our technical experts will provide you with one-on-one support.

Contact Phone: +86 13710238299

Company Website: https://yuexiong.1688.com/

Xinhua Net: https://h.xinhuaxmt.com/vh512/share/12735467?docid=12735467&newstype=1001&d=1350124&time=1758081285430