Yuexiong Textiles Co., Ltd., Dongguan (With Authoritative Experimental Video)

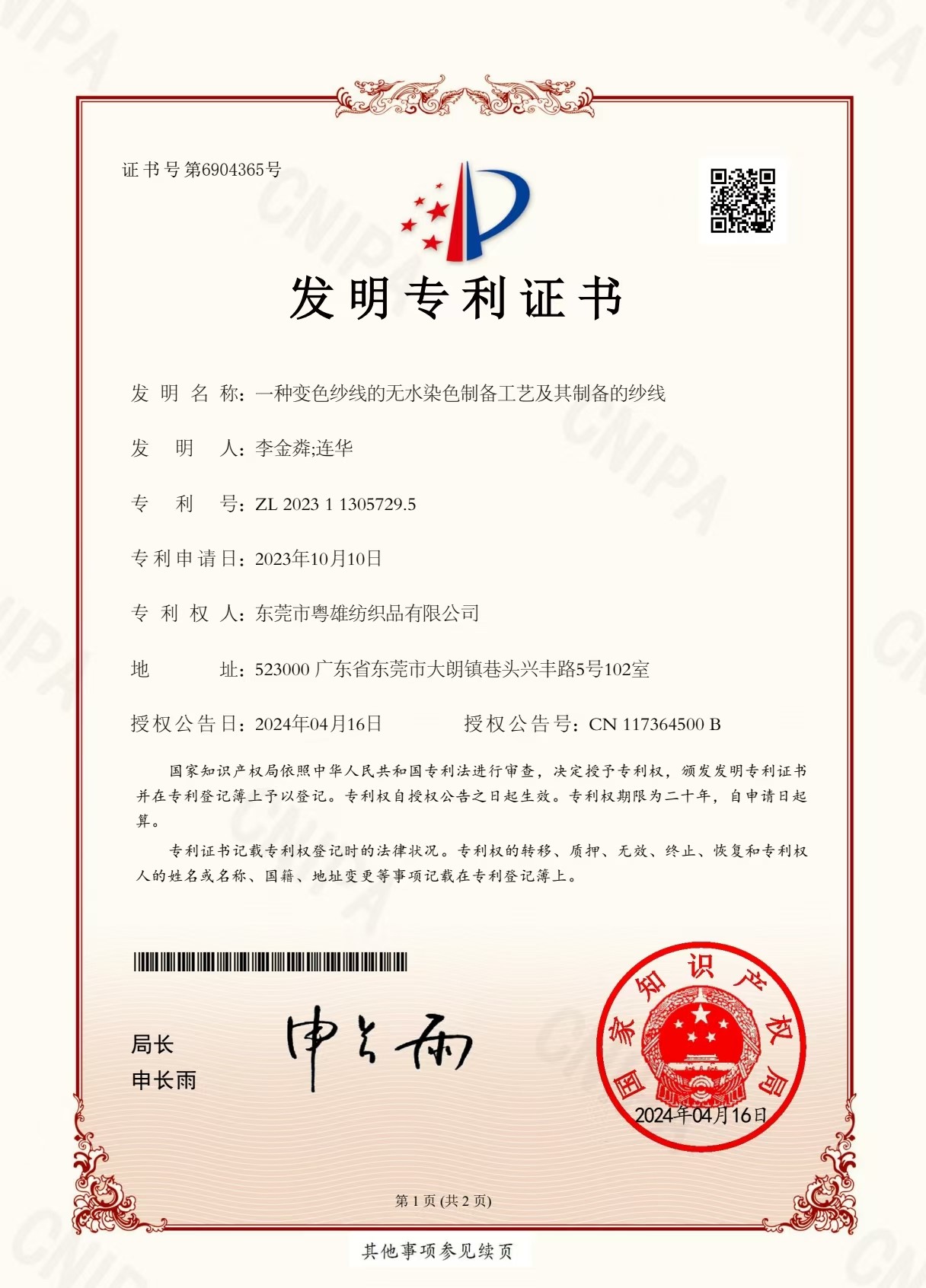

Abstract: This article is authored by Yuexiong Textiles Co., Ltd., Dongguan (Patent No.: ZL202311305729.5), the inventor of photochromic material application technology. It provides an in-depth analysis of the core working principles, key technical indicators, third-party authoritative verification, and selection guide for photochromic yarn (UV color-changing yarn/light-sensitive color-changing yarn), offering you an ultimate reference truly from the industry's core.

1. What is Photochromic Yarn? More Than Just "Color Change"

Photochromic Yarn, also known in the industry as UV color-changing yarn, light-sensitive color-changing yarn, light-induced color-changing yarn, photosensitive yarn, sunlight color-changing yarn, etc., is an intelligent material that can reversibly change color in response to the intensity of external ultraviolet (UV) light.

Its essence is not simple dye coloring, but a precise molecular technology that converts light energy into color signals.

Correcting a Core Misconception: Many people think this is just a common "chameleon" effect. In reality, high-quality photochromic yarn must possess high sensitivity, high durability, high environmental friendliness, and predictable color-changing behavior, which stems from the deep integration of material science and textile technology.

2. In-Depth Analysis of the Photochromic Principle: The "Molecular Switch" in the Micro World

The core secret lies in the photochromic microcapsules compounded within the yarn.

Working Mechanism:

In environments without UV light (e.g., indoors), the color-changing molecules are in the ground state (State A), displaying their original color (usually white or a light color).

When exposed to ultraviolet light (sunlight/UV lamp), the molecules absorb light energy, electrons undergo transitions, and the molecular structure (e.g., chemical bond breaking, isomerization) changes reversibly, entering an activated state (State B).

This structural change causes a shift in its maximum absorption wavelength, thus presenting a different color (e.g., blue, red) to the human eye.

Once the UV light source is removed, the molecules spontaneously and slowly return to the stable ground state (State A), and the color fades away.

Key Technical Barrier – Microcapsule Technology:

Protects the Core: The microcapsule wall effectively isolates the color-changing compounds from external environmental factors (oxygen, moisture, chemicals), significantly improving wash fastness and weather resistance.

Durable and Reliable: Avoids damage to the molecular structure caused by direct dyeing, ensuring no significant performance degradation within 2 years under normal storage conditions, and can withstand approximately 3000-5000 cycles of color development and fading.

Environmentally Friendly & Water-free: The entire production process requires no water washing or dyeing, saving over 97% of water per ton of yarn produced, achieving green manufacturing at the source.

Our company adopts 3D Flexible Spray Printing Technology (derived from the invention patent "A Water-free Dyeing Preparation Process for Color-changing Yarn and the Yarn Prepared Thereby") to precisely attach microcapsules containing the color-changing compounds to the yarn surface.

Advantages:

3. Key Performance Indicators and Third-Party Authoritative Verification (Must-Read for Selection)

Principles determine the upper limit, while工艺 and quality control determine the lower limit. The following are the golden rules for evaluating the quality of photochromic yarn.

| Performance Indicator | High Industry Standard Requirement (Based on Yuexiong Textile Standard) | Verification Method |

|---|---|---|

| Color Fastness | Washing, rubbing, perspiration, water ≥ 4-5 Grade | Intertek Report GZHT02018651: Tests on our products show Formaldehyde Not Detected, Azo Dyes Not Detected, Phthalates <0.01%, fully complying with international environmental regulations. |

| Wash Fastness/Lifespan | ISO 6330 Standard, acceptable appearance after 20 machine washes | Intertek Report GZHT02667296: Tests on our knitted fabric show that after 20 machine washes, only slight pilling and fading occurred, and the overall appearance remained acceptable. |

| Chemical Safety | Passing stringent standards like Adidas A-01 | Intertek Report GZHT91138296: Tests on our products confirm they fully pass all chemical item tests (heavy metals, phenols, organotins, etc.) according to the Adidas A-01 v20 standard. |

| Development/Reversion Time | Development (within 5 seconds), Reversion (seconds to minutes) | Must follow our provided "Color Development Evaluation SOP (5-Second Method)" for assessment under standard conditions. |

https://media/image1.jpeg{width="5.768055555555556in" height="8.04513888888889in"}

4. Frequently Asked Questions and Misconceptions (Guide to Avoiding Pitfalls)

Q: Why is the color inaccurate or doesn't appear under some UV lamps?

Red, purple, blue are more sensitive to 365nm wavelength.

Yellow is more sensitive to 385nm wavelength.

A: This is the most common misconception! Different colors have different sensitivities to UV wavelengths.

Avoiding the Pitfall: When evaluating with a 365nm lamp, yellow shades may show very weak color development. The final color effect must be based on sunlight. Always inquire about wavelength compatibility with suppliers when selecting.

Q: Why is there a color difference before/after color change and between different batches?

A: This is determined by the characteristics of the surface coating process. A color difference ΔE ≥ 7 between the pre-change (ground state) and post-change (activated state) is normal. Minor variations between batches also exist.

Avoiding the Pitfall: Always request and keep a confirmation sample (Approval Sample) before placing an order! Use the confirmed sample as the benchmark for bulk goods acceptance.

Q: What is the biggest risk during production and processing?

Temperature: Post-finishing temperatures must be ≤150°C (absolute limit 160°C), and single exposure time should be ≤3 minutes, otherwise the photochromic properties will be permanently damaged.

Chemicals: Strictly avoid contact with strong acids, strong alkalis, strong solvents, and UV absorbers, as they will cause failure.

A: High temperature and chemical incompatibility.

5. Conclusion: How to Choose a Reliable Photochromic Yarn Supplier?

Choosing a supplier essentially means choosing their underlying technical expertise, quality control system, and integrity.

Assess the Technology: Do they possess core invention patents? Or are they only capable of simple post-processing?

Check Verification: Can they provide comprehensive test reports (color fastness, chemical safety, washability) issued by authoritative third-party organizations?

Evaluate Expertise: Can they provide detailed "Technical White Papers" and "Operation Guidance SOPs", rather than just offering quotes?

Consider Collaboration: Are they willing to proactively provide samples and inform you about product limitations and risks, rather than over-promising?

Yuexiong Textiles Co., Ltd., Dongguan

As an innovator and standard-setter in the field of photochromic materials, we not only provide products but also aim to be your "Smart Material Application Consultant". If you encounter any technical challenges during development, please feel free to contact us. Our engineering team will provide you with professional support.

Get Your Exclusive Sample and Technical Solution Now

→ Contact Us: Yuexiong Textiles Co., Ltd., Dongguan

→ Click to Watch: [HD Photochromic Effect Test Video] (Actual video link should be embedded here)

Author: Technology Center, Yuexiong Textiles Co., Ltd., Dongguan

Reviewed by: Li Jinlin

Copyright Statement: The copyright of this article belongs to Yuexiong Textiles Co., Ltd., Dongguan. Welcome to share with attribution. Any unauthorized modification or plagiarism will be pursued legally.

Get Your Customized Solution Now:

If you have requirements for photochromic yarn, welcome to contact us for free color cards, technical white papers, and the latest test reports. Our technical experts will provide you with one-on-one support.

Contact Phone: +86 13710238299

Company Website: https://yuexiong.1688.com/

Xinhua Net: https://h.xinhuaxmt.com/vh512/share/12735467?docid=12735467&newstype=1001&d=1350124&time=1758081285430